The AlphaLab is a bench-top leak tester dedicated to flexible packaging testing for the food, pet care and cosmetic Industries. It has been specially designed for laboratories in Factories that have to follow stringent Quality Inspection procedures and processes like ISO 22000 & HACCP.

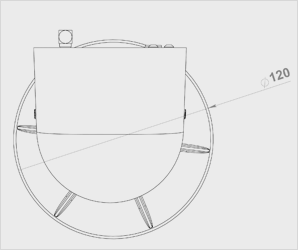

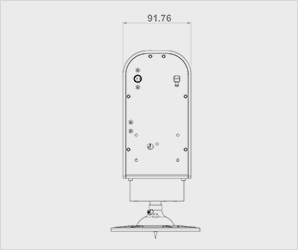

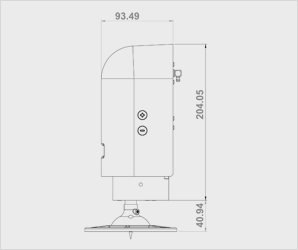

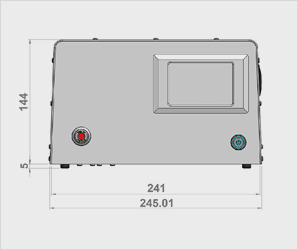

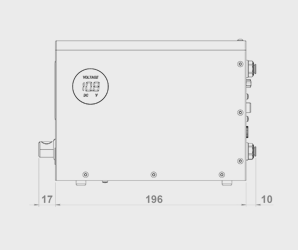

It is made up of an AlphaLeakTester and an AlphaTower.

The AlphaLab is used for leak testing and altitude simulation.

The altitude simulation is designed to identify the altitude at which your packaging will start to leak when subjected to pressure differences such as during air transport.

To test your packaging, place a sample under the perforating tower of the AlphaLab, adjust the tower manually downwards until it is in contact with the sample, the test begins. You can test as many samples as you wish.

Full digital results are immediately available (the AlphaLab will measure leaks > 5 μm), visible on a screen, they can be transmitted to your computer via a USB connection.

Warranty: 3 years.